As discussed in the previous article, inverse latex polymers like Sepineo™ P 600 or Sepineo™ D.E.R.M exhibit strong thickening capabilities of polar solvents, even with high solvent content or complex solvent/co-solvent systems.

These polymers can be used to formulate a large range of dosage forms (gel, cream-gel, Geltrap™, emulsion, ...) fitting your API and formulation needs.

Cream-gel: a performant & flexible vehicle

|

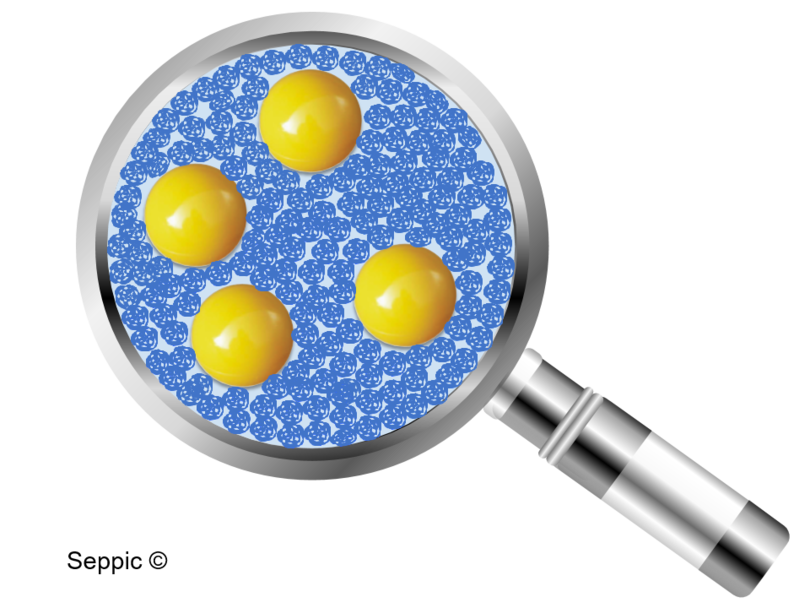

An inverse latex polymer is characterized by a strong elastic polymeric network, allowing it to stabilize oil phases without requiring additional surfactant. The resulting dosage form is a Cream-gel, where the oil droplets are entrapped in the microgel polymer network. |

|---|

An inverse latex polymer is characterized by a strong elastic polymeric network, allowing it to stabilize oil phases without requiring additional surfactant. The resulting dosage form is a Cream-gel, where the oil droplets are entrapped in the microgel polymer network.

Sepineo™ P 600 or Sepineo™ D.E.R.M can be used to simultaneously stabilize large amounts of solvents & oils in a cream-gel, with high flexibility of formulation parameters.

25% Solvent / 30% oil cream-gel

- API solubilization: the capacity of a cream-gel to stabilize all nature of solvents allow you to build a customized vehicle matching the physico-chemical properties of your specific API.

- Targeted skin permeation: you can freely adjust the concentration of solvents / oils / penetration enhancers to match a specific skin permeation profile. A Cream-gel vehicle may be used for therapeutic action on the skin surface to transdermal applications

- No HLB calculation required, this stabilization process is not dependent on the oil nature.

- Contrary to a traditional emulsion process, a cream-gel can be manufactured through both room-temperature or hot process, with low or high shear process, without impact on the viscosity or stability of the final drug.

Geltrap™: a great dosage form for texture optimization

|

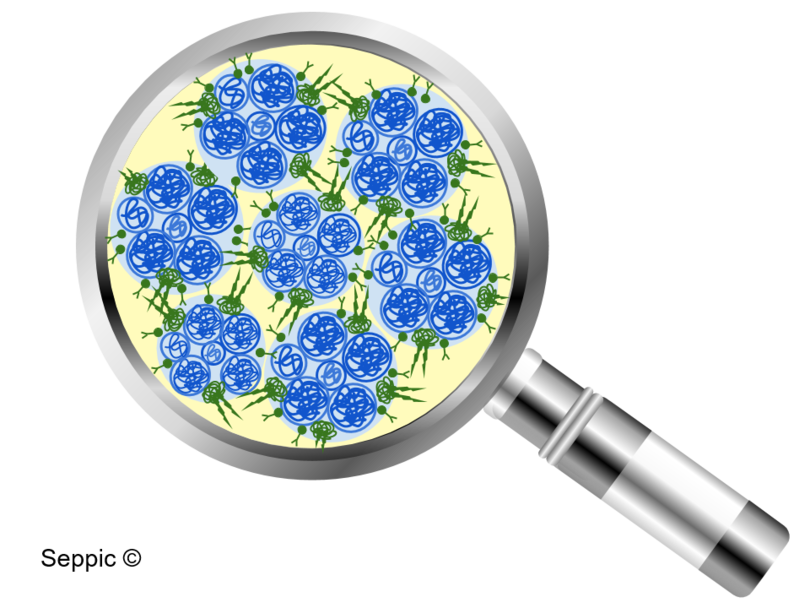

A Geltrap™ or Gel-in-oil emulsion is an innovative dosage form which can incorporate a high amount of polar solvent in its internal phase while giving to a formula a fresh touch and pleasant sensorial profile for an optimal patient compliance. |

|---|

- High aqueous internal phase content (> 80%), with a large compatibility with all polar solvents (PEG 400, diethylene glycol monoethyl ether, propylene glycol, …) thickened by an inverse latex or associative polymer.

- Typical Geltrap™ texture is characterized by a fresh touch, non-greasy nor tacky even with high amounts of solvents, with better texture compared to other conventional dosage forms.

- The Gel-in-oil emulsion is stabilized by a polymeric emulsifier like Simaline™ L80, allowing for a successful emulsification even at room-temperature with low shear agitation.

O/W Emulsion: the most robust vehicle

|

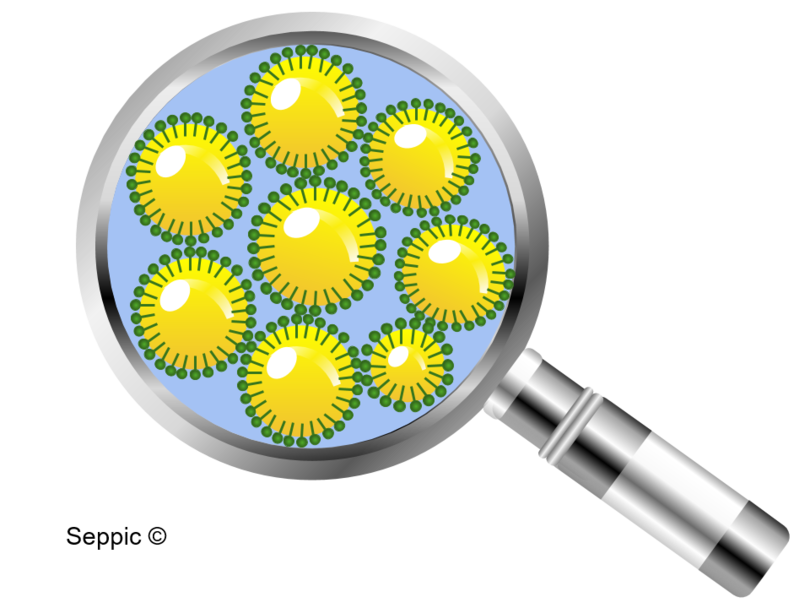

Associating a polymer with a strong polymer network and the surface tension lowering effect of surfactants is a synergistic approach to obtain stable emulsions in the most challenging circumstances. |

|---|

Sepineo™ SE 68 (Cetearyl alcohol - cetearyl glucoside) is a non-ionic emulsifier with an ether-glucoside bond, further strengthening your emulsion for the addition of the most challenging APIs.

- Stable emulsion for addition of ionic API or APIs combination.

- Formulation of high concentrations of solvents and/or oily phase.

- Stable over a pH range from 2 to 11 without hydrolysis of the ether bond compared to conventional ester bond.

- Rheofluidifying for an homogeneous spreading.