Formulation

Mastering the formulation of our customers' products

Formulation can be defined as the art of combining ingredients to meet a user's needs. And whether that need is to protect, strengthen, treat, beautify, or clean, no one ingredient used on its own – and at a reasonable dose – can completely satisfy it.

For Seppic, mastering the formulation of its customers' end products is a source of innovation to create new ingredients with enhanced performance, formulated ingredient compositions that make it easier for our customers to use, or to propose new formulation or gesture concepts. Drawing on this expertise, we also provide our customers with personalized assistance from design to production.

Global skills

Formulation is a global field which requires a general scientific knowledge, and know-how from practical experience. This can be highly specific depending on the formula’s intended application and desired properties. Effective formulation requires the combination of:

- A good knowledge of the ingredients, their roles, their mechanisms of action and their interactions, because mastering the compatibility of the compounds to be mixed is an essential parameter.

- Knowledge of emulsology and of the different forms of mixture such as solutions, dispersions, and physico-chemical phenomena that govern their use, such as solubilization or emulsification. Formulations are often fine dispersions of several mutually immiscible phases such as water and oil in an emulsion. These are so-called metastable colloidal systems: the formulation appears homogeneous on the macroscopic scale, but is heterogeneous on the microscopic scale, and therefore liable to be unstable over time. The formulation’s stability throughout its duration of use is a major concern for formulators and requires knowledge of the phenomena that occur at the interfaces of different phases.

- A mastery of mixing technologies and equipment and of their mode of action, for example, different homogenization techniques including high pressure for the manufacture of emulsions; or granulation, atomization, film coating, encapsulation, grinding, or compression for dry forms.

- Knowledge of the final application and the behavior of the formulation in use, as well as a detailed understanding of user needs that also takes into account environmental impacts.

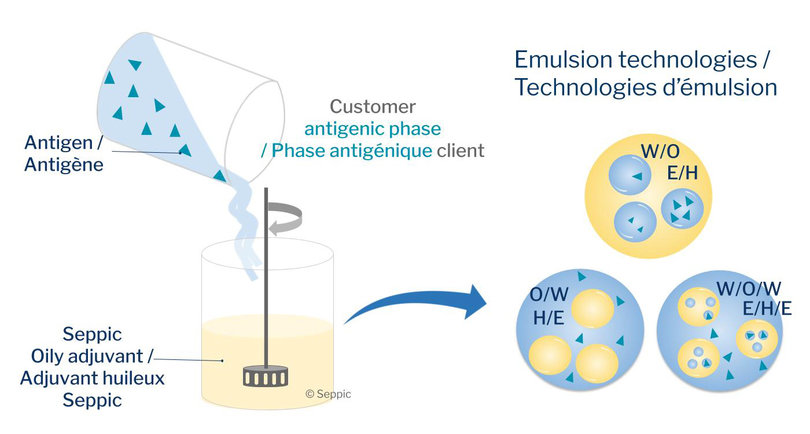

Seppic has expertise across multiple types of formulations: mixtures of liquids or of liquids and powders such as solutions; dispersions, gels, foams, emulsions; and so-called dry forms consisting of mixtures of powders, or whereby the majority proportion is powder. As surfactant specialists, we’ve mastered emulsology – the science of emulsions – to implement all types of emulsions: oil-in-water (O/W), water-in-oil (W/O), multiples, micro and nano emulsions. Physico-chemical characterization and sensory analysis make it possible to characterize formulations and their performance.

Formulation expertise for topical route

To take better account of customer and user needs, and for finer analysis of how the formula behaves in its field of use and route of administration, Seppic has developed specific expertise relating to customers’ businesses.

For this reason Seppic has developed expertise in the formulation of cosmetic and dermopharmaceutical products, which resulted in creation of two concepts of cold emulsions: cream-gel and Geltrap™. These formulations, offering very different sensory profiles to a conventional emulsion, are designed from stabilizing ingredients, polymers with adequate rheological profiles, and a liquid emulsifier for Geltrap™. Geltrap™ has also demonstrated its usefulness in the creation of a perfuming ritual with good hold of the perfume on the skin without ethanol.

Seppic also works on the characterization of the applicative performance of excipients and active ingredients for skin and hair care, and on the interactions between molecules and natural biological processes, such as thinning, wrinkle formation, skin pigmentation, etc.

For example, Seppic developed the Montanov™ emulsifiers for cosmetics, such as Montanov™ 68, and Sepineo™ SE 68 for dermopharmacy, which contribute to skin hydration. In a recent study, conducted ex vivo by X-ray micro-diffraction, a very simple emulsion containing Montanov™ 202 was applied to the surface of the skin. It was possible to follow the emulsion’s fate after application and to understand that hydration is linked to an insertion within the lipids of the stratum corneum, which thus reinforces the cutaneous barrier.

|

Scientific communication |

Seppic also produces prototype formulas. Each year, more than 10,000 samples of prototype formulas are sent to cosmetics and dermo-pharmaceutical manufacturers, serving as inspiration in their own developments.

Expertise in formulation for oral route

For the oral route, Seppic develops pharmaceutical or food-grade film-coating compositions, drawing specifically on its expertise in film-coating and tablet formulation to help its customers create products that specifically meet their requirements. Seppic has combined this expertise to develop Sepifilm™ White TF, a ready-to-use, white film-coating composition without titanium dioxide, for nutraceutical and pharmaceutical tablets.

Expertise in formulation for parenteral route and vaccines

Thanks to its expertise in the development and manufacture of injectable excipients, Seppic provides technical support for its customers to develop and formulate specific injectable excipients.

Seppic also designs adjuvants for human and veterinary vaccines and optimizes formulations to be stable, effective and well-tolerated. For veterinary vaccines, these formulations notably are tested in our immunology laboratory at the Veterinary School of Maisons-Alfort (France). The wide variety of compositions of our adjuvants gives access to vaccine formulations of all types, such as water-in-oil, oil-in-water or multiple emulsions. For veterinary vaccines these can be adapted to both the specificity of the disease, and animal concerned.

The adjuvant formulations are also optimized to meet specific administration routes. For example, an adjuvant for of vaccines in the form of microemulsions, Montanide™ IMS 1312 VG, was developed for the vaccination of fish by immersion.