Lipoaminoacid technology

Creating high-performance ingredients inspired by life

Lipoaminoacid chemistry creates life-inspired ingredients with increased biological performance or interfacial properties.

At Seppic, this chemistry, at the crossroads of amino acid chemistry and oleochemistry, has given rise to two major families of ingredients: concentrated active ingredients with multiple biological performances, and liquid, foaming biosourced surfactants.

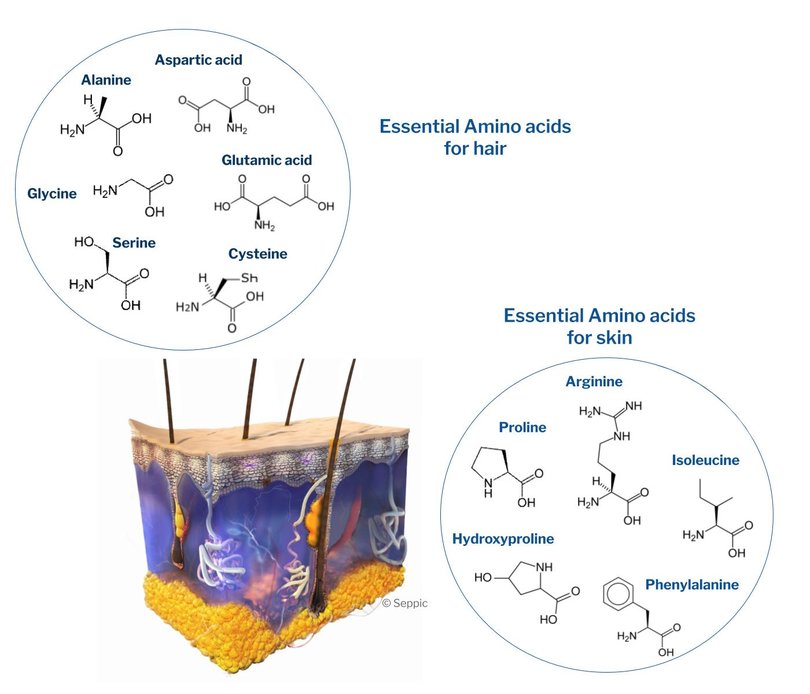

Amino acids, an essential resource

Amino acids, given the diversity of their structure and omnipresence in nature, constitute an essential resource for the creation of bio-inspired ingredients. As essential components of proteins, amino acids are encoded by the DNA of the cells of all living beings and play a determining role both in the structure of organisms, and their biological metabolisms. Originating from plant sources or biotechnologies, they are carboxylic acids with an amine functional group. While their general structure is NH2 – HCR – COOH, they differ in terms of the R group side chain.

Amino acid transformation

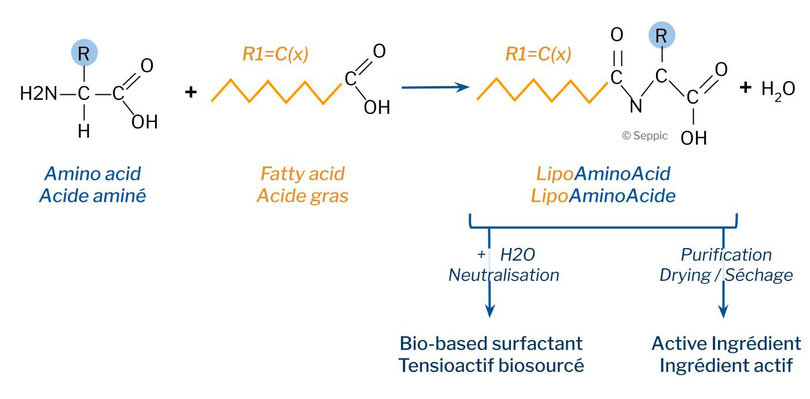

Amino acids are naturally hydrophilic molecules, potentially anionic or cationic depending on the pH. Grafting one or more hydrocarbon chains gives them an amphiphilic character, which amplifies their biological effects or surface properties. This is the essence of lipoaminoacid technology.

On the one hand, grafting hydrocarbon chains (acylation) improves their solubilization in hydrophobic media (lipophilization). This facilitates their vectorization in living media and increases their bioavailability to create active ingredients with multiple biological targets. On the other hand, depending on the hydrocarbon chain selected, the amphiphilic character gives the possibility of creating biosourced surfactants.

One advantage is that lipophilization processes are carried out in a single step at room temperature without sophisticated catalysts. The sources of lipophilic chains essentially come from fatty acid derivatives, which themselves originate from the oleochemical sector. Following this transformation, the lipophilized amino acids, also called lipoaminoacids, are subjected to two types of finishing operations. These come in two forms, either as aqueous solutions with a lipoaminoacid concentration of between 20 and 40%, or else in powder form with a high concentration of lipoaminoacids (>90%). In both cases the compositions, whether liquid or solid, are perfectly defined, and each constituent analytically quantified.

Lipoaminoacids, concentrated active ingredients for multiple purposes

Acylation technology combines various amino acids and fatty acids with a chain length of 8 to 16 carbons that exist in nature. Adding a purification and drying step creates an inexhaustible source of concentrated active ingredients that can be used for cosmetics with a wide variety of biological targets.

By creating a bank of more than a hundred molecules, and combining analytical characterization and biological screening in vitro, Seppic has developed a range of active ingredients with anti-aging, lightening, purifying, or soothing functionalities. The nature of the lipoaminoacid biological activity is intimately linked to the structure of the two starting constituents.

| Ingredient | Amino acid (R) | Fatty acid (R1) | Biological activity |

|---|---|---|---|

| Lipacide™ C8G | Glycine | C8 | Purification |

| Lipacide™ UG | Glycine | C11’ | Purification |

| Sepiwhite™ MSH | Phenylalanine | C11’ | Lightening |

| Adiposlim™ | Proline | C12 | Slimming |

| Sepicalm™ S WP | Asp/Glu/Gly/Ala | C12 | Soothing |

| Sepilift™ DPHP | Hydroxyproline | C16 | Anti-wrinkle |

| TimeCode™ | Glycine | C16 | Anti-age / Skin radiance |

| Voluform™ | Isoleucine | C16 | Firming |

Lipoaminoacids in solution, biosourced, foaming, or solubilizing surfactants

Lipoaminoacids in solution, with fatty chain length of 8 to 18 carbon atoms, are surfactants with remarkable foaming properties.

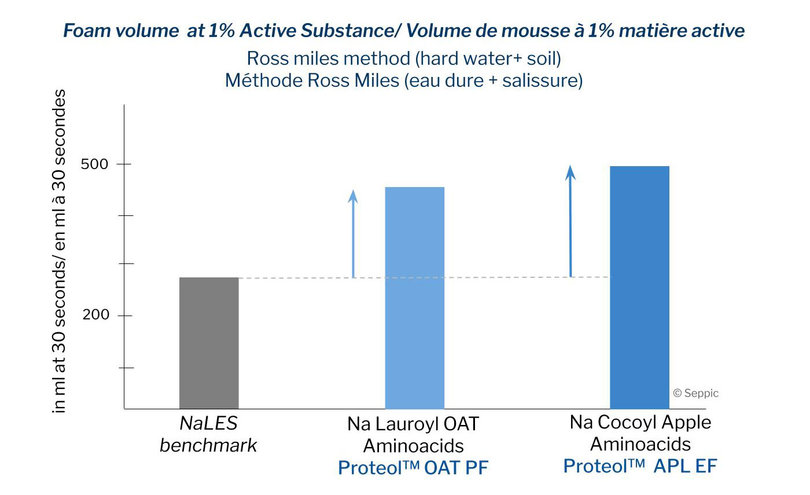

In cosmetics, acylation technology has given rise to a family of mild surfactants for cleaning the skin and hair. One such surfactant is Proteol™ OAT PF, based on the reconstituted amino acid profile of oat, or Proteol™ APL EF, based on the reconstituted aminogram of apple juice. These surfactants offer major advantages to users, such as a high-foaming power with a dense foam with great stability in the presence of hard water and dirt, and a characteristic soft and creamy feel.

Finally, thanks to remarkable foaming properties, this technology is used to create innovative and sustainable foaming ingredients for multiple industrial applications. Their biodegradability, and non-ecotoxic, non-bioaccumulative nature, become a major advantage when used for tunneling drilling operations, aquifers (lubrication, recovery of cuttings), or as ingredients for cement factories, or the elicitation of plants.

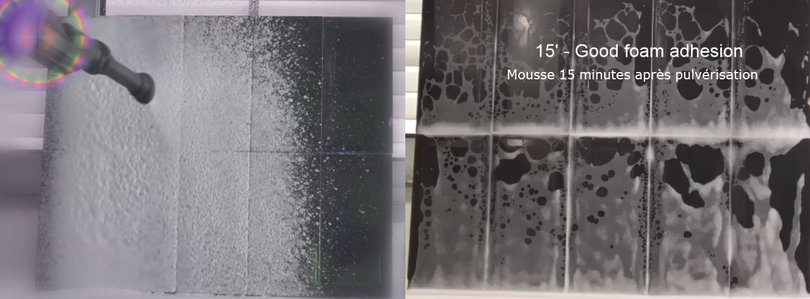

By combining bio-based alkylpolyglucosides from sugar chemistry and a glutamic acid N-acyl derivative, Seppic has developed Montaline™ CG 26, a patented high-performance foaming surfactant. By combining two technologies, it is possible to obtain a dense, stable and robust foam, both in a wide pH range from 4 to 10, and in the presence of hydrogen peroxide for example. The accelerated wetting kinetics and superior adhesion of this foam on vertical walls, are an asset for detergency, fire protection and disinfection of contaminated solid surfaces.