Cold emulsion

From innovative textures to energy saving

Seppic's GeltrapTM gel-in-oil and cream-gel technologies produce cold emulsions and save energy used when making formulations, while providing innovative textures and multiple sensory experiences. Seppic has pioneered these technologies in the cosmetics sector.

GeltrapTM gel-in-oil

Geltrap™ is a technology for producing gel-in-oil emulsions composed of a high internal gelled water phase thickened by a polymer, and a low external oily phase stabilized by a liquid xylolipidic emulsifying system.

A Geltrap™ emulsion is produced in a simple cold process by mixing the gelled phase, and the oily phase containing the emulsifier, using low or high shear equipment. Gel droplets, fragmented during mechanical agitation, are stabilized in the oily phase.

This technology has many advantages:

- From fluid to thick textures,

- A simple and robust formulation to stabilize active ingredients sensitive to heat, glycols, inorganic sunscreens, pigments,

- Rationalized ingredient composition,

- Stabilization of all types of oily phases (vegetable oils, esters, silicone oils, mineral oils, etc.).

The benefits of this technology to consumers include a contrasting effect between freshness and softness, feelings of hydration and emollience even at low oil content, and also being long-lasting and water-resistant.

|

Scientific communication |

The cream-gel

The cream-gel is similar to an emulsion with an aqueous continuous phase but without added surfactant. The oily phase is stabilized by a suitable thickening-stabilizing-texturing polymer.

The cream-gel is easily produced by mixing its three components -- water, oil, and polymer -- using conventional equipment. The precisely dosed elasticity of the polymer network stabilizes the oil droplets effectively and durably. The oil droplets, fragmented during mechanical agitation, are trapped in the polymer’s microgel network.

Cream-gel technology has many advantages:

- Wide formulation pH range from 3 to 12,

- Maximum stabilization of 45 to 50% of oily phases depending on the performance and dose of the polymer,

- Suitable for active ingredients sensitive to heat.

As such, consumers can be offered products with a white appearance and a smooth and shiny texture, in a variety of textures ranging from sprayable fluids to thick gels.

|

Scientific communication |

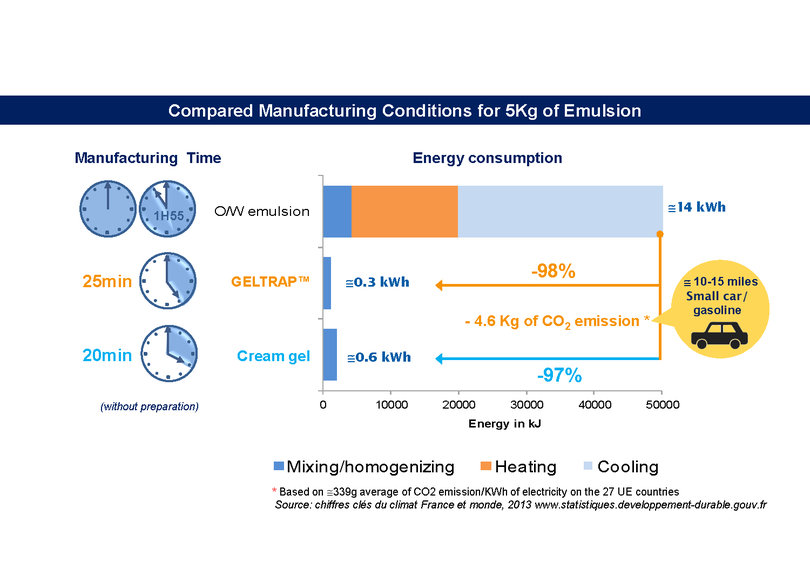

Make savings with cold technologies

The production of Geltrap™ and cream-gel saves energy and reduces manufacturing time. For the production of 5 kg of emulsion:

- Geltrap™ saves up to 98% of energy and 80% of manufacturing time,

- The cream-gel saves up to 97% of energy and 80% of manufacturing time,

compared to a conventional oil-in-water hot emulsion.

|

Scientific communication |

Excellence in polymerization technology

GeltrapTM Gel-in-oil and cream-gel are innovative technologies in the field of cold process. They rely on the mastery of polymerization technologies. Seppic polymers are pre-neutralized and ready to use. Obtained by inverse emulsion or by precipitation, they are available in liquid or powder form.

The long-term stability of cold emulsions is guaranteed by the well-balanced visco-elastic rheological profile of the polymers and by their high shear strength.