Cuq Arnaud Elodie, Cécile Taillebois, Alicia Roso

2021, 26 TH IFSCC CONFERENCE

Introduction:

When thinking about formulation sustainability, ingredients naturality often takes center stage, as a focal point for communication with end consumers. However, hair care, associated with large volume production, justifies lending also attention to the formula manufacturing process. The aim of this work was, in a first step, to investigate the possibility of reaching a cold processable consistent hair mask base, using a combination of a liquid thickening-conditioning material and biobased ingredients. The efficacy of the cold-processed formula was challenged ex vivo compared to classic hot-processed hair masks.

Methods:

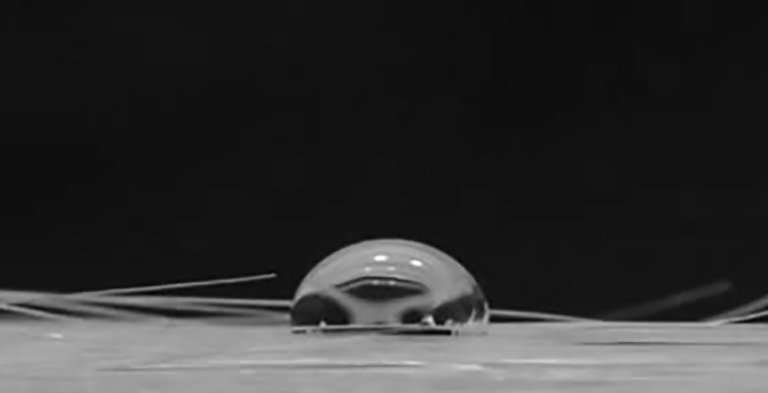

Controls consistent hair masks, requiring a hot process, were formulated by combining fatty alcohols, shea butter, natural gelling agent, biobased alternative to silicon oil, argan oil and traditional cationic agent, as key components. Trials were made with similar compositions containing a liquid thickening-conditioning polymer at same cationic active substance, followed by removal of solids, one by one, until reaching a cold-processed formulation (classical characterization & stability monitoring). Efficacy of the optimized cold-processed base was assessed after a single application on double-bleached damaged caucasian tresses, compared to a hot-processed conditioning benchmark for unruly hair and untreated group (5 replicates; application of 0.5 mL; 55 ± 5% relative humidity; 22 ± 2 °C; ANOVA & Dunnett’s post-test analysis for comparison with untreated group; Student’s t-test, bimodal & unpaired for formulations comparison; 95% confidence interval). Wet and dry combing was mechanically measured (EMIC DL-500 test equipment) and reduction of combing energy was calculated versus untreated group. Hair wettability and porosity were evaluated before and after application, using contact angle (Software ImageJ-1-47v) of a drop of water on the hair surface and time of drop absorption (increasing angle value reflected increasing surface hydrophobicity; increasing time reflected decreasing hair porosity). SEM-FEG observations (Zeiss Supra55VP; triplicate) were done to investigate film-forming properties of the thickening-conditioning polymer on virgin brazilian hair before and after iron straightening (cold-processed hair mask versus placebo without polymer).

Results:

The comparative formulations demonstrated the performance of the liquid-conditioning material to reach a consistent hair mask base while removing one by one all the solid ingredients. At each step, the resulting simplified mask base was more consistent than the hot-processed reference (equivalent active concentration of conditioner). Both cold-processed mask and hot-processed benchmark demonstrated significant decrease in combing energy compared to baseline. Cold-processed mask was equivalent to the benchmark on dry combing (80% energy reduction). Significant increase in contact angle was observed after application of cold-processed hair mask reflecting increased surface hydrophobicity, associated with decreased water porosity, both signaling some restoration of the fiber protection. SEM hair observations evidenced the mode of action linked to the film-forming properties of the polymer, able to resist high temperature.

Discussion and Conclusion:

The study demonstrated the interest of the tested liquid thickening-conditioning polymer to design efficient and simplified high consistency cold-processed hair mask bases with high naturality level. Significant effects have been demonstrated after a single application and could be completed by investigation of cumulative effects.

Seppic, 50 boulevard national, 92257 La Garenne Colombes, France